1) DUT (the target device (SSDT) containing suspected evidence

2) The physical medium (USB) to carry the source data to the examination tool

3) The examination tool (ET) used to extract and harvest evidence

It is possible to extrapolate even greater numbers of inter-connected entities but then it would be simpler, if I were to do that, to simply write a book instead of writing this blog post. Moreover, greater numbers of inter-connections exponentially introduce the potential for higher risk of failure relevant to an entity's MTBF (mean time between failure) and MTTF (mean time to failure).

[”British scientist, Sir William Thomson (Lord Kelvin, 1824 - 1907),

concisely captured the aspect of knowledge so that others can study

the observations and apply the results without having to repeat the

experiment, when he wrote: “When you can measure what you are

speaking about and express it in numbers, you know what you are

talking about.”]

SSDT - USB - ET provides a useful basis upon which to consider metrological traceability:

"A core concept in metrology is metrological traceability,[7] defined by the Joint Committee for Guides in Metrology as "property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty".[8] Metrological traceability permits comparison of measurements, whether the result is compared to the previous result in the same laboratory, a measurement result a year ago, or to the result of a measurement performed anywhere else in the world."

http://en.wikipedia.org/wiki/Metrology#Metrological_traceability

An excellent source of reference for definitions for the science of measurement is:

International vocabulary of metrology — Basic and general concepts and associated terms (VIM)

Vocabulaire international de métrologie — Concepts fondamentaux et généraux et termes associés (VIM)

http://www.bipm.org/utils/common/documents/jcgm/JCGM_200_2008.pdf

International vocabulary of metrology – Basic and general concepts and associated terms (VIM) 3rd edition (2008 version with minor corrections)

Vocabulaire international de métrologie – Concepts fondamentaux et généraux et termes associés (VIM)

3e édition (Version 2008 avec corrections mineures).

http://www.bipm.org/utils/common/documents/jcgm/JCGM_200_2012.pdf

Why have I shown two versions of the same document? Traceability is the answer. Building a quality system requires identification of reference materials upon which test measurements are (or have been in the past) conducted. Anyone involved in lab preparation and of running a lab should be aware that standards iso17025 and iso9001 identify principles that may be adopted for a wide range of industries etc. It is only when drilling down into how these principles should be applied in practice does one become aware of how, metaphorically speaking, naked one is without something or someone else pointing to a path to follow.

VIM is an acknowledged and established international standard that can be referenced for defining the naming conventions for testing. Of course, there is still the need for knowledge, skill and experience for operating under lab conditions. Early works of Scroggie and Johnstone even today provide useful observations about various aspects of testing involved in a laboratory environment can be found in Radio and Electronic Laboratory Handbook 1980 edition (Marcus Graham Scroggie and George Gordon Johnstone ISBN 0-408-00373-1 and ISBN 13: 9780408003735). The book is available from Amazon and from reputable booksellers.

There are a range of other reference materials from testing through to calibration. For instance NASA (Deep Space Network) http://deepspace.jpl.nasa.gov/dsndocs/810-005/214/214-1.pdf ; Laboratories for the Design and Assembly of Electronic Devices using Surface Mount Components conferencepaper.pdf ; Handbook of Laboratory Experiments in Electrical and Electronics Vol.3 (Adamu Murtala Zungeru; James G. Ambafi ISBN 9781497507203) ; and the list goes on. These reference materials are in addition to publications produced by the FBI, NIST, ACPO etc...

This discussion started out by referring to the physical medium USB to carry the source data from the DUT to the examination tool (ET). The relevance of doing so is that if the examiner eliminates the medium as the cause for failure or corrupted evidence then the logical conundrum that remains, is the DUT can be at fault, is the ET can be at fault or are both DUT/ET together faulty?

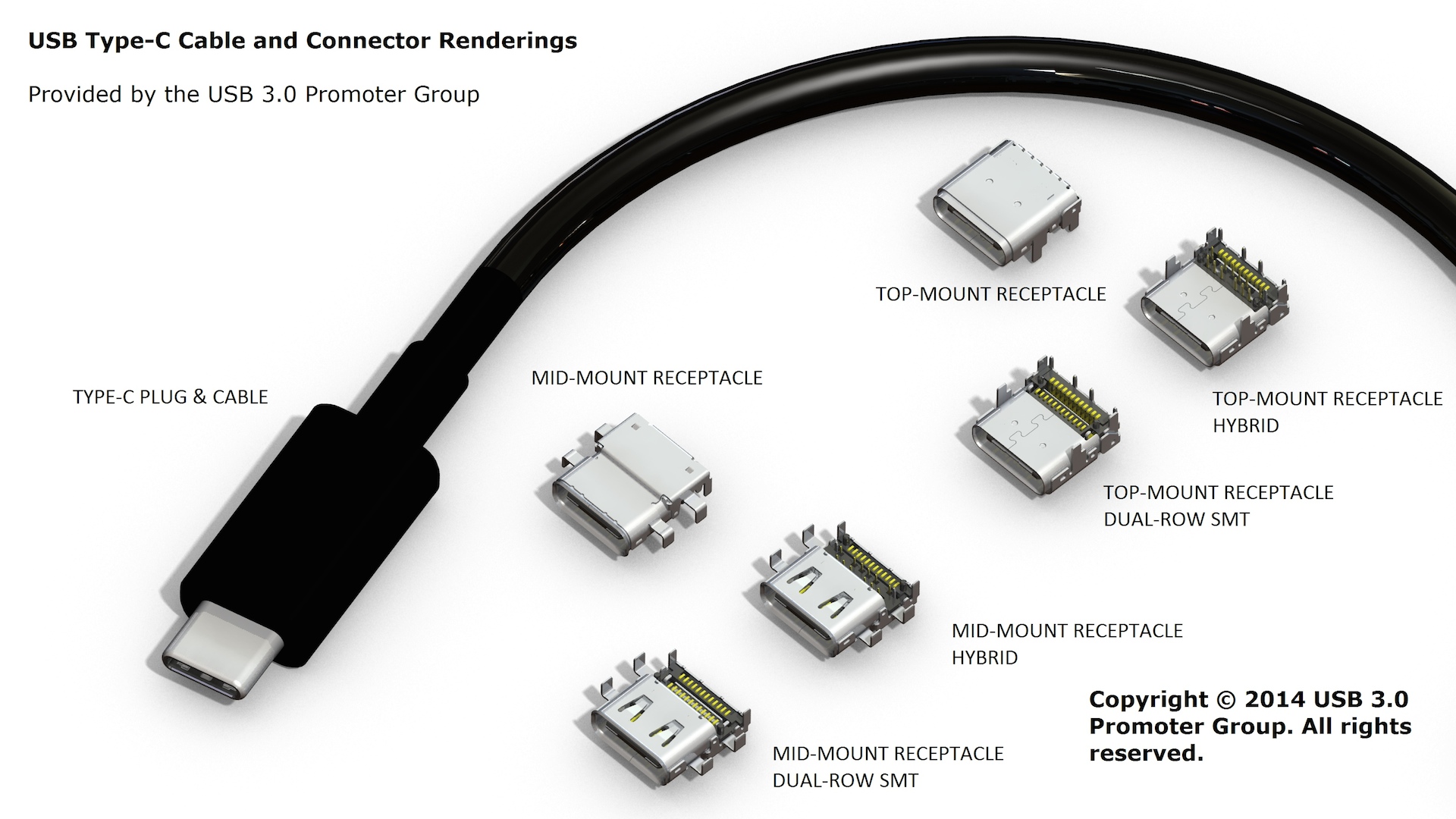

To understand the technical properties for USB look here:

USB Type C

http://www.usb.org/developers/usbtypec/

http://www.usb.org/developers/docs/

http://www.usb.org/developers/docs/usb_31_060115.zip

This version of USB specification is identified, not simply from personal experience, but due to industry adoption of the standard:

(a) http://www.usb.org/press/USB_Type-C_Specification_Announcement_Final.pdf

(b) http://arstechnica.com/gadgets/2014/08/small-reversible-usb-type-c-connector-finalized/

Image credited to http://arstechnica.com/gadgets/2014/08/small-reversible-usb-type-c-connector-finalized/

(c) https://support.apple.com/en-gb/HT204360 etc...

A testing schedule for MTBF and MTTF cannot be created unless the device class using a version of the USB specifications is corroborated:

Device Classes (some useful resource materials)

http://www.usb.org/developers/docs/devclass_docs/

http://www.atmel.com/dyn/resources/prod_documents/doc4322.pdf

http://www.linux-usb.org/usbnet/

http://cscott.net/usb_dev/data/devclass/usbcdc11.pdf

Moreover, if USB 3.0 is backward compatible with USB 2.0 could USB 3.0 be used as the de facto standard for all SSDTs to assist defining MTBF and MTTF?

What about USB plug/port sizes, would these create different test requirements?

Lastly, and to close Part 1 of this blog discussion, there is another question equally worth asking: "Does a manufacturer's/supplier's warranty for 12 or 24 months mean that lab testing is not necessary for that period of the warranty in question?

Previous discussion under Metrology

http://trewmte.blogspot.co.uk/2015/05/metrology.html

Knowing DUT memory

http://trewmte.blogspot.co.uk/2015/05/knowing-dut-memory.html

No comments:

Post a Comment